how to measure aluminum thickness|common aluminum sheet thickness : white label This simple formula allows you to measure the thickness of aluminum foil. Use the formula: \text{thickness} = . webFirst, make sure you understand the question, ask clarifying questions of your own if needed. Decide if you want to answer the question: you have the option to divert, delay or return. If you do answer, use this simple structure: Answer the question with a quick, simple, direct answer. Add additional ‘bullets’ if needed.

{plog:ftitle_list}

Siga-nos. QUESTION tradução: pergunta, pergunta, questão, dúvida, interrogar, questionar, questão [feminine], pergunta.. Veja mais em Dicionário Cambridge inglês-português.

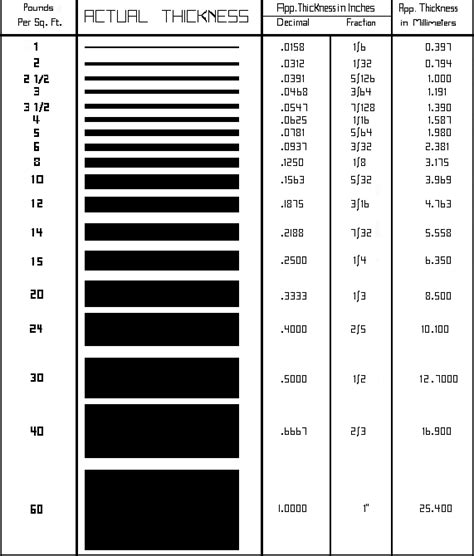

How to Measure Sheet Metal Thickness? There are two ways to measure sheet metal: using a measuring tape (which is less precise) and a . Aluminum sheet gauge is a standardized measurement system used to indicate the thickness of an aluminum sheet metal. Understanding the gauge system is essential when selecting the right aluminum sheet for various . The chart below can be used to determine the equivalent sheet thickness, in inches . This simple formula allows you to measure the thickness of aluminum foil. Use the formula: \text{thickness} = .

Sheet metal gauge charts are invaluable tools in the metalworking industry. They provide essential information about the thickness of the sheet metal to help you choose the perfect measurement for your design. For this . Calipers can measure the inner diameter, outer diameter, length, width, thickness, step difference, height, and depth of aluminum sheets, pipes, and other materials. Calipers are the most commonly used and convenient .

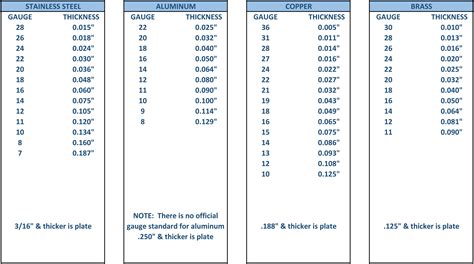

Guide to Material Thickness – Stainless Steel, Aluminum, Copper, & Brass. Gauges are used to measure the material thickness of a sheet of metal. These units are neither standard of metric and are completely . Gauge conversion chart can convert aluminum plate between gauge and thicknesses (inches and mm). Convenient weight calculation and purchase.

visual thickness chart

If you order 10 gauge aluminum, you’re going to get a physical measurement of 0.102.” That’s a 0.033” difference, which is well outside the tolerances for most designs. Using the wrong gauge chart can be a big . Dive into The Machining Properties of 6061 Aluminum Grades and optimize your metal operations. Learn only the best practices here! Start now. Call Us Now . They provide essential information about the thickness of the . Take for instance 12-gauge thickness across the material types listed below; stainless steel is 0.105″ thick, aluminum is 0.080″, copper is 0.108″, and brass is 0.081″. . You can use any number of calipers to measure the .

Manufacturers measure the thickness of aluminum foil using a micrometer which measures the width to one-thousandth of an inch, represented as mils.

The height of foil is correlated to the thickness while measuring the thickness of aluminum foil. Given below is a simple formula to estimate the thickness of foil: Calculating The thickness: Using the above formula, we can calculate the thickness of foil. If, for example, we have a piece of foil, 16cm in length, 20cm in width and weighs about . Film Thickness Measurement. The most common means of measuring the thickness of anodized aluminum is the Eddy Current Method (Figure 1). The Eddy Current Method uses a probe that contains a coil. This probe/coil is driven by a high–frequency oscillator to generate an alternating high-frequency field. What’s the best way to measure thermal spray aluminum thickness on a non-magnetic (austenitic) stainless steel? A. Accurate measurement of thermal sprayed aluminum (TSA) coating thicknesses is important for both the applicator and the end user. The applicator wants to apply the correct thickness and minimize material costs. Measurement of film thickness can be done with many different instruments. Understanding the equipment that is available for paint thickness measurement and how to use it is useful to every coating operation. . The wet-film comb is a flat aluminum, plastic, or stainless steel plate with calibrated notches on the edge of each face. .

Understanding how aluminum foil is measured is the first step to obtaining foil thickness. Being familiar with the increment of measurement will help in understanding the thickness once obtained. Manufacturers measure aluminum foil thickness in Mils. Below is what a mil is and how a mil appears numerically. 1 Mil = 1 Thousandth of an inch. Step 2: Identify the Type of Sheet Metal. Sheet metal can come in a variety of materials such as aluminum, stainless steel, or copper.Each material has its own unique properties and thicknesses, so it is important to identify the type of sheet metal you are working with before taking measurements. Measure diagonally from the other top corner to the other bottom corner. Compare the measurements. Replacement windows will typically allow for these measurements to be different by up to 1/4 inch. If your measurements are different by more than 1/4 inch, you may need to note an adjusted width measurement. Run a level from one top corner of the .

This means that 16-gauge steel, aluminum, and brass will each have distinct thicknesses despite sharing the same gauge number. . The concept of “gauge” as a thickness measure emerged during the American Industrial Revolution, driven by wire manufacturers’ need to quantify their products. Initially, they employed a gravimetric method . When we make a product we specify the thickness as a mil. How do you visualize such a small dimension? In order to help people understand what the mil thickness of a product is, I try to give them a point of reference. For example, I always explain that the 30 mil (30 divided by 1,000 = .030) Geomembrane is about the thickness of a credit card. Measuring coating thickness over an aluminum alloy substrate can be accomplished using a conventional eddy current channel to measure the paint thickness according to a standard. With no human intervention (the operator may not even know whether parts are made of steel or aluminum), the instrument automatically selects duplex or eddy .

Wire gauge calculations Wire diameter calculations. The n gauge wire diameter d n in inches (in) is equal to 0.005in times 92 raised to the power of 36 minus gauge number n, divided by 39:. d n (in) = 0.005 in × 92 (36-n)/39. The n gauge wire diameter d n in millimeters (mm) is equal to 0.127mm times 92 raised to the power of 36 minus gauge number n, divided by 39:

You can measure the gauge on either round solid wire (an individual wire with no insulation) or stranded wire (a number of strands wrapped together). To measure the gauge of a piece of wire, you’ll need to strip any insulation (the plastic coating which surrounds the wire), and then use a wire-gauge tool to measure the size.

Metal gauge thickness (aka gage thickness) dates back to the 1800s, before a unit of measure for thickness was universally agreed upon. It is a way of measuring the thickness of material via density. . For example, . STK: A measurement of starting raw material thickness. Contrary to belief, the expanding process does not directly alter material thickness. Strand Thickness should not be confused with the overall height or depth of . With checker plate products there is a lot of misinformation around the thickness of the material and how it is measured. Most reputable aluminium suppliers and manufacturers will agree that when .

How strong is aluminum diamond plate? According to industry standards, the strength of aluminum diamond plate primarily depends on its thickness and the design of the diamond pattern. Generally, common thicknesses of aluminum diamond plate range from 1/16 inch to 1/4 inch, with bending strengths typically falling between 10,000 and 30,000 psi. Accurately measuring the thickness of aluminum foil is important for a variety of projects. This article explores how to measure the thickness of aluminum foil using a ruler and simple math, as well as various tools that can be used to ensure accurate measurements.

typical aluminum sheet thickness

Measuring Thickness of Chromate on Aluminum. The thickness is generally too low to affect dimensional tolerance, and weight is generally a better description than thickness. No passwords, No popups, No cost . Since chromate conversion coatings are gels it is difficult to measure thickness directly. It is usually reported in milligrams per .

Learn how to measure window screens. The DIY way to accurately get screen measurements for windows. If your existing window screens have at least one side of the width and of the height not bent. Then you can easily measure your replacement screen by measuring the existing window screen. Measure and write down the width by length. To calculate the thickness of aluminum foil, you will need a few basic tools and measurements. To begin, you will need a ruler or tape measure, a piece of aluminum foil, and a flat surface to work on. Lay the aluminum foil flat on the surface, making sure there are no wrinkles or creases in the foil. Using the ruler or tape measure, measure the .to the thickness measurement of non-metal coatings like paint, which makes magnetic or eddy current gages more adequate for these measurements. Still, XRF is ca-pable of measuring the weight or the thickness of sig-nificantly thin coating layers of few atomic layers up to the so-called saturation thickness (typically in the range

Remember, you can often get away with running out the tile adhesive near to the edge of the tile where the trim sits to make a smaller trim fit if necessary, so if you have a 10mm tile and you can only fit in a 10mm trim then this is possible, but remember that this is not ideal, and will result in a weaker tile trim fixture.PosiTector 6000 FN measuring paint thickness on an aluminum hood Eddy Current Principle for Aluminum. Paint thickness over all other metals such as aluminum is measured using an eddy current technique. When the instrument’s probe is brought near a metal (conductive) surface, a coil within the probe generates an alternating magnetic field that .

BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at 50 percent of the material thickness. In Machinery’s Handbook, the K-factor for mild cold-rolled steel with 60,000-PSI tensile strength is 0.446 inch. This .

plastic impact testing techniques

thickness of aluminum sheet metal

web5 de ago. de 2023 · Follow the Austrian Bundesliga Sturm Graz and LASK with Eurosport. The match starts at 5:30 PM on August 5th, 2023. Catch the latest Sturm Graz and .

how to measure aluminum thickness|common aluminum sheet thickness